Göktuğ GÖKÇEN

MECHANICAL ENGINEER

Welcome!

Hi, I'm Göktuğ!

With my passion for engineering, design, and production processes, I’m here to provide innovative solutions tailored to your needs.

On this platform, you can explore my projects, experiences, and areas of expertise. From 3D design to laser cutting, additive manufacturing, and machining services, you’ll find everything I have to offer.

If you’re ready to dive into inspiring projects and explore the exciting world of engineering, I invite you to join me on this journey.

Enjoy your visit!

Project

Managing

English

B2

English

B2

Reverse

Engineering

MS

Office

Project

Planning

CAD

Solidworks

Hello, I’m Göktuğ. I was born in Bursa and graduated from the Mechanical Engineering department at Karabük University. My interest in engineering began at a young age, which led me to develop a deep passion for this field. As a child, my curiosity about technological devices and interest in mechanical systems constantly pushed me to think in a solution-oriented way. This early discovery motivated me to focus my life on engineering and commit to improving myself in this field. Since 2020, I have been working with a desire to continuously innovate and develop high-quality solutions in the fields of design and manufacturing engineering. Throughout my career, I have gained valuable experience working in many sectors, and I have developed both technically and managerially.

I have been involved in many projects, successfully implementing designs such as mechanical furniture, industrial and desktop CNC machines, mobile industrial machines, coating lines, and turnkey factories. I actively participated in all stages of the projects, including design, production, assembly, and customer delivery. My goal in every project was to achieve efficient, reliable, and high-quality results, always focusing on innovation and practicality at every step to achieve the best outcome. Additionally, I contributed to efforts aimed at improving production processes and enhancing plant ergonomics, creating safer and more efficient work environments.

My passion for creating innovative solutions has led me to establish two business ventures: NGG Makine and Ahtapot Mühendislik. At NGG Makine, I design and sell desktop CNC machines, providing high-quality solutions to meet various industrial needs. On the other hand, at Ahtapot Mühendislik, I offer consulting, assembly, and project planning services, working closely with clients to deliver tailored solutions in design and manufacturing engineering. Both ventures allow me to stay at the forefront of technological developments while continuously pushing the boundaries of engineering innovation.

Engineering Manager

I was responsible for the design, project planning, purchasing, and commissioning of Cataphoresis and Electroless Nickel Plating lines. I coordinated all stages of the process, ensuring timely and efficient execution while meeting technical requirements.

At the same time, I managed our own Electroless Nickel Plating line, overseeing operations, maintaining quality standards, and implementing improvements to enhance efficiency.

Project Engineer

I was responsible for project planning, purchasing, and design in a project supported by TÜBİTAK and Celtic-Next. My role included ensuring alignment with project goals, technical specifications, and timelines.

I also performed duct and capacity calculations for ventilation systems and handled the design, planning, and purchasing for paint and coating facility projects. This allowed for smooth integration and efficient execution of the systems.

Project Engineer

I contributed to designing the layout plan and process flow for a semiconductor factory owned by parmisun, planned to be established in Dubai. My role focused on optimizing production workflows, organizing critical manufacturing areas like wafer fabrication and testing, and aligning the facility design with Parmisun's vision for efficiency and innovation.

The project also involved addressing location-specific challenges, such as Dubai's environmental conditions and regulatory requirements. Collaborating with Parmisun and other stakeholders, we aimed to create a cutting-edge facility that positions Dubai as a key player in advanced semiconductor manufacturing.

Design & Product Development Manager

Throughout my career, I took proactive steps to address engineering and manufacturing challenges, providing solutions tailored to the needs of each business. This hands-on approach enabled me to successfully complete three different models of Man-Lift systems and deliver one EPS factory project, all while ensuring quality, efficiency, and customer satisfaction at every stage.

I managed the entire design and manufacturing processes of turnkey factories, including EPS, Construction Chemicals, and Plaster factories. My role involved planning and overseeing all stages of these projects, from initial concept to final delivery. I also led numerous R&D projects, with a particular focus on the development of Man-Lift systems, ensuring they progressed smoothly from idea conception to successful customer delivery.

Desing & Manufacturing Engineer

I was responsible for planning and overseeing the design and manufacturing processes of various machines, including 4-axis CNC lathes, CNC routers, woodworking machines, and special design CNC machines. My role encompassed the entire lifecycle of these projects, from initial planning and design to manufacturing and final implementation.

Throughout my career, I successfully started and completed multiple projects, including two 5-axis CNC lathes, three 4-axis CNC routers, and one specially designed CNC multi-lathe. Each project required a high level of precision and innovation, ensuring the machines met the specific needs of our clients and adhered to the highest industry standards.

Mechanical Engineer

I managed the Reverse Engineering activities at CREOMobilya, a newly established subsidiary. My responsibilities included overseeing the entire manufacturing planning process, from the creation of detailed designs to ensuring the product reached the customer. This involved designing molds, mechanical furniture systems, installation/user manuals, and packaging. Additionally, I played a key role in the purchasing process and the installation of the ERP system, ensuring smooth operations across departments.

.jpeg)

%20(2).jpeg)

%20(1).jpeg)

.jpeg)

Our Services:

-

Engineering Consultancy: We offer strategic guidance at every stage of your projects, developing the most suitable solutions for your design and manufacturing processes with our expert team.

-

Project Planning: We design functional and efficient projects based on customer requirements, striving for excellence at every step using engineering science.

-

Laser Cutting: We provide precise laser cutting services for materials such as wood, acrylic, and others, ensuring detailed and high-quality production.

-

Additive Manufacturing (3D Printing): Using advanced additive manufacturing technologies, we offer solutions ranging from prototype production to the final product.

-

Assembly Services: We handle the assembly, quality control, and on-site installation of the machines we produce, ensuring smooth and reliable operation.

Ahtapot Mühendislik provides engineering consultancy, project planning, laser cutting, additive manufacturing, and assembly services, offering tailored solutions for every engineering need in the industry. With a commitment to high-quality service, we approach each project with a customer-centric focus, analyzing needs accurately to achieve the most efficient results.

At Ahtapot Mühendislik, we combine innovation with engineering expertise to ensure the highest level of customer satisfaction in every project. We are here to meet all your needs with innovative solutions tailored to your industry.

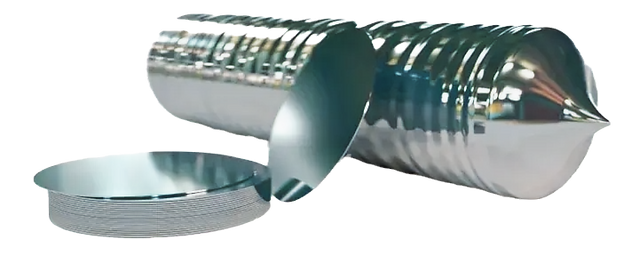

I managed the entire manufacturing process by optimizing custom-designed machines according to customer needs, including desktop CNC routers, CNC lasers, and 3D printers. This involved everything from the initial design phase to selecting the appropriate materials, implementing precise mechanical and electrical systems, and ensuring the final product met the highest quality standards.

I worked closely with clients to understand their specific requirements and provided tailored solutions that improved their production efficiency and capabilities. My approach was always focused on delivering practical, reliable, and high-performance machines that could meet a wide range of industrial applications.